Micro body cooling system

- participación

Portable Body Cooling System|AC Cloth

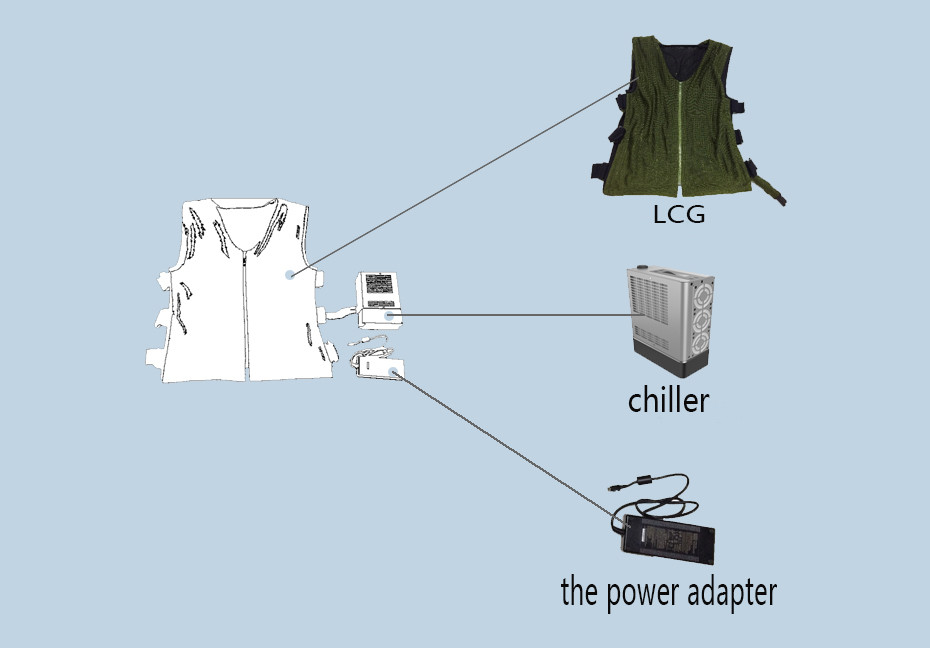

This product is a micro environment cooling system foe human body, including a Micro refrigeration mainframe with refrigerating capacity of 200W, LCG, Battery, bags, charger and accessories, the product is designed by portable belt or backpack, which is easy to carry.

This product is used for all kinds of needs of the portable use of body cooling, including: chemical forces, special operations, traffic police, firefighters, medical rescue, racing, fishing, tourism and outdoor enthusiasts and other groups.

1. Features

①Small and lightThe miniature compression expansion refrigeration products using self-research heat exchangers are the smallest and lightest in the similar products. | ②High temperature control accuracyThe temperature can be manually set on the touch screen, and the product can achieve the temperature control accuracy of 1 degrees centigrade. |

③Easy operationThe refrigeration efficiency of the small micro refrigeration system is about 2, which is 5 times of the semiconductor refrigeration efficiency, and is far higher than other refrigeration and cooling methods. | ④High electric efficiencyThe refrigeration efficiency of the small micro refrigeration system is about 2, which is 5 times of the semiconductor refrigeration efficiency, and is far higher than other refrigeration and cooling methods. |

⑤High reliability and safetyProduct development through a series of reliability and safety testing. The factory production of each product must go through the corresponding type test (vibration, pressure, high and low temperature environment, weather resistance, oil return, condensation, protection, liquid pump / fan components such as reliability, performance, electrical safety etc.). | ⑥Good environmental adoptability(1) Cooling or heating in temperature of 50 ℃~-40℃. Temperature can be continuously controlled from -20℃~ 35℃.(2) Adapt to 0.5 ~ 1 atmospheric pressure (high altitude) working environment. (3) Response quickly according to temperature changing. (4) Adapt to mobile sloshing environment (transportation, people carry). (5) According to the requirements, it have the corresponding level of waterproof and dustproof function, electromagnetic compatibility, medical device certification. |

2. Product Parameters

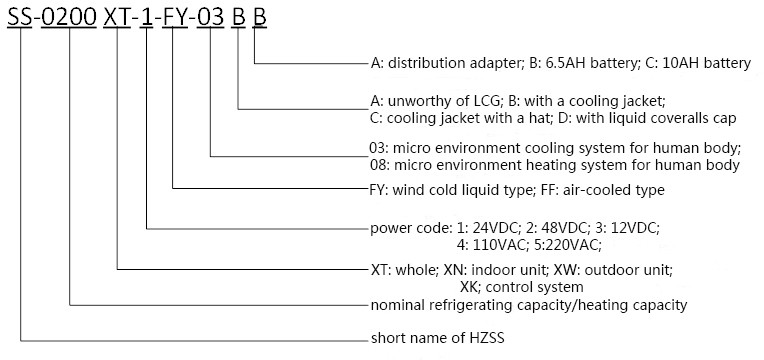

2.1 Naming Rules

2.2 Configuration

| No. | Component type | Component name | Component description |

|---|---|---|---|

| 1 | Host | Compressor | Miniature DC variable frequency compressor |

| 2 | Evaporator | Microchannel heat exchanger | |

| 3 | Condenser | Parallel flow microchannel heat exchanger | |

| 4 | Refrigerant | R134a | |

| 5 | Display panel | Touch panel | |

| 6 | Cooling clothes | Fabric/Lining | Standard |

| 7 | Cooling water pipe material | Food grade plastic pipe | |

| 8 | Water interface | Matching quick joint | |

| 9 | Housing | Shell | Surface treatment of aluminum alloy shell by anodic oxidation. |

| 10 | Battery and charger | Li-On rechargeable | 3D lithium batteries |

| 11 | Charger | Supporting |

2.3 Host parameters

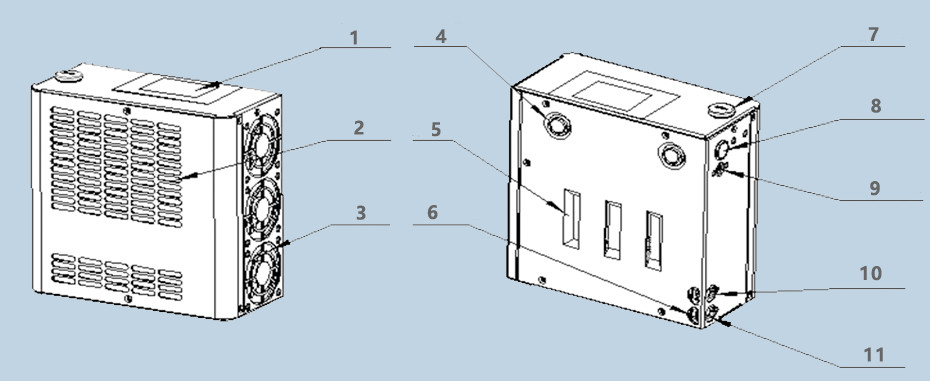

| 1 | Touch pannel | 7 | Water filler |

| 2 | air inlet | 8 | power switch |

| 3 | air outlet | 9 | power connector |

| 4 | strap ring | 10 | water inlet |

| 5 | strap groove | 11 | water outlet |

| 6 | release button |

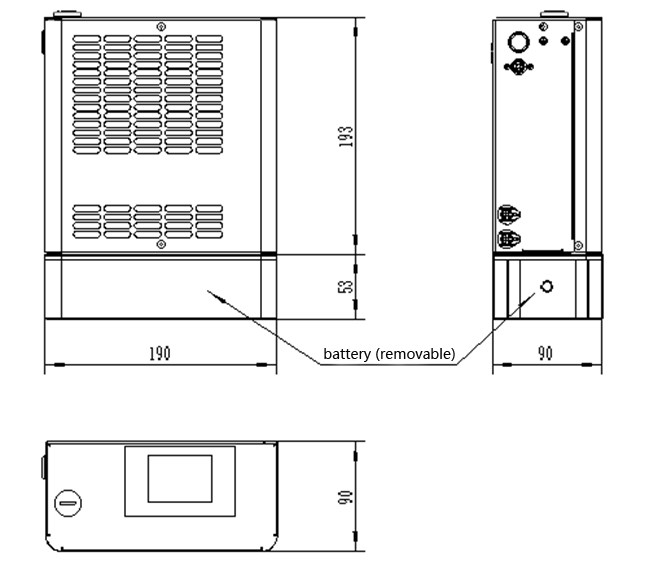

2.4 Host Dimension

2.5 Cooling Cloth Style

a.Lquid cooling jacket |  b.Liquid cooling jacket with hood |  c.Liquid cooling suit with hood |

2.6 Technical specification sheet

| Project | Unit | Numerical value |

|---|---|---|

| Nominal refrigerating capacity | W | 200 |

| Nominal power | W | 110 |

| Main input voltage | V | DC24 |

| Rated voltage of host | A | 4.6 |

| Rated current of host | A | 9.0 |

| Range of output water temperature | °C | Advice:16.03~5.0 |

| Dimension | mm | Length:190 |

| Width:90 | ||

| High:193 | ||

| Temperature control mode | Touch screen settings, host self-control | |

| Working environment temperature | °C | +10~+50 |

| Storage environment temperature | °C | -30~+70 |

| Net weight of host | kg | 2.5 |

| Host noise | dB(A) | 55 |

| Circulating medium | 100% pure water or distilled water | |

| Appearance material | Aluminum(1.Silvery 2.Blue 3.Black 4.Others ) | |

| Note:Nominal working condition: The ambient temperature is 45°C centigrade. The liquid temperature is 25 degrees centigrade °C. | ||

| Project | Performance | Remarks |

|---|---|---|

| Nominal voltage | 22.2VDC | 200 |

| Working voltage | 19.0~25.2VDC | |

| Nominal capacity | 6.5 AH(Standard)or 10AH | |

| Working temperature | Charge:0℃ ~45℃ | |

| Discharge:-10℃~60℃ | ||

| Storage temperature | 3 monthes:-20~45℃ | When stored, check regularly to keep the battery in power condition. |

| 6 monthes:-20~30°C | ||

| Net Weight | 0.9 or 1.4kg |

| Input voltage range | AC 100-240V |

| Rated input voltage | AC 220V |

| Input frequency range | 47~63HZ |

| Input current | 2.5A Max(@AC 180V,Full Load) |

| Work efficient | 85% Min(@220V AC,Full Lord) |

| Charging voltage | 25.2V DC |

| Charging voltage range | 25.2~25.5V DC(Ref:25.3V DC@empty Lord) |

| Charging current | 4.0A |

| Working temperature | -30~45°C |

| Storage temperature | -40~75°C |

| Working humidity | 0~90% |

| Storage humidity | 0~90% |

| Cooling method | Natural air cooling |

| LED instructions | ||

|---|---|---|

| Charging state | green | red |

| Waiting for charging | ON | OFF |

| Plug in batteries | OFF | ON |

| Charging completed | ON | OFF |

| Output short circuit | FLASH | FLASH |

| Output reverse connection | ON | OFF |

| Temperature resistance ℃°C | As Demand | |

| Material | Nylon + Spandex(No water pipe) | |

| Liquid connector | Self-closing fast plug joint | |

| Washing method | Put it in laundry bag | |

| Weight(kg)(kg) | Liquid cooling jacket | 0.85 |

| Liquid cooling jacket with hood | 1.00 | |

| Liquid cooled coveralls cap | 1.20 | |

3.Performance

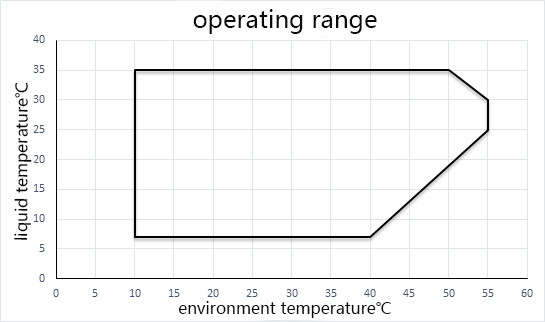

3.1 Working range

Note:Working over range for a long time, the host will warmming.

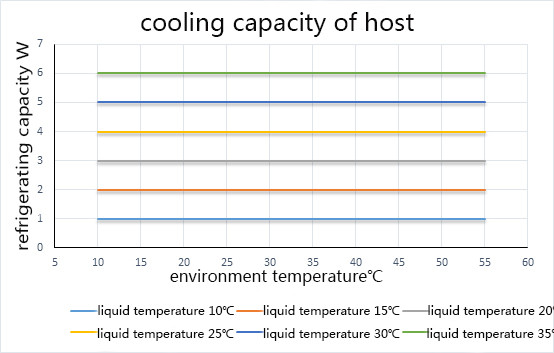

3.2 Cooling Capacity

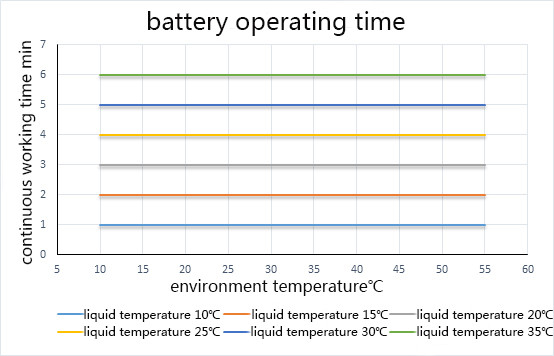

3.3 Battery working time

4. Fault code

| Code | Fault | Code | Fault |

|---|---|---|---|

| F1 | Compressor overload/condenser fouling | F21 | Disconnection of water pump |

| F2 | Compressor self-protection | F22 | Pump overload/water filtration blockage |

| F3 | Compressor communication failure | F26 | Environmental temperature sensor fault |

| F4 | High temperature protection of compressor | F27 | Liquid temperature sensor fault |

| F11 | Fan 1 broken line | F28 | Fault of inlet temperature sensor |

| F12 | Fan 2 overland | F41 | Liquid or liquid flow is low |

| F13 | Fan 3 broken line | F42 | Environmental temperature anomaly |

| F14 | Fan 1 overload | F43 | Anti-freezing protection |

| F15 | Fan 2 overland | F44 | Overvoltage/under voltage of power supply |

| F16 | Fan 3 overload | F21 | Pump line broken |

Note: When some fault occur, the host will continue to operate, but it will automatically take some recovery measures or alternative measures. | |||